Building Envelope Surveys

BuildScanIR™ provides building envelope surveys to identify and resolve issues impacting building safety, integrity, or value. Our experts have extensive experience detecting and addressing a range of defects, including stucco delamination, CMU wall testing and much more.

Designed to help protect your investment, minimize costly repairs, and ensure that your building meets all necessary standards and specifications, our service is an essential tool for building owners and developers. Contact us today to learn more about how we can help you identify and address construction defects.

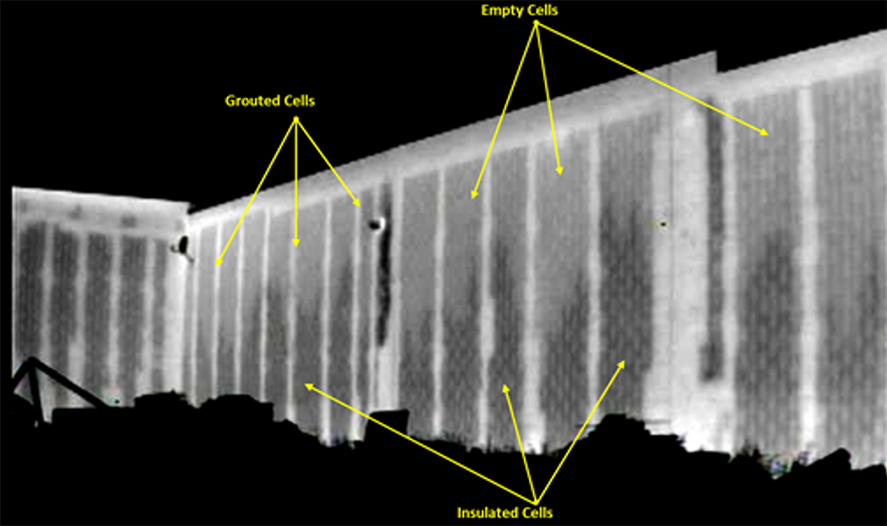

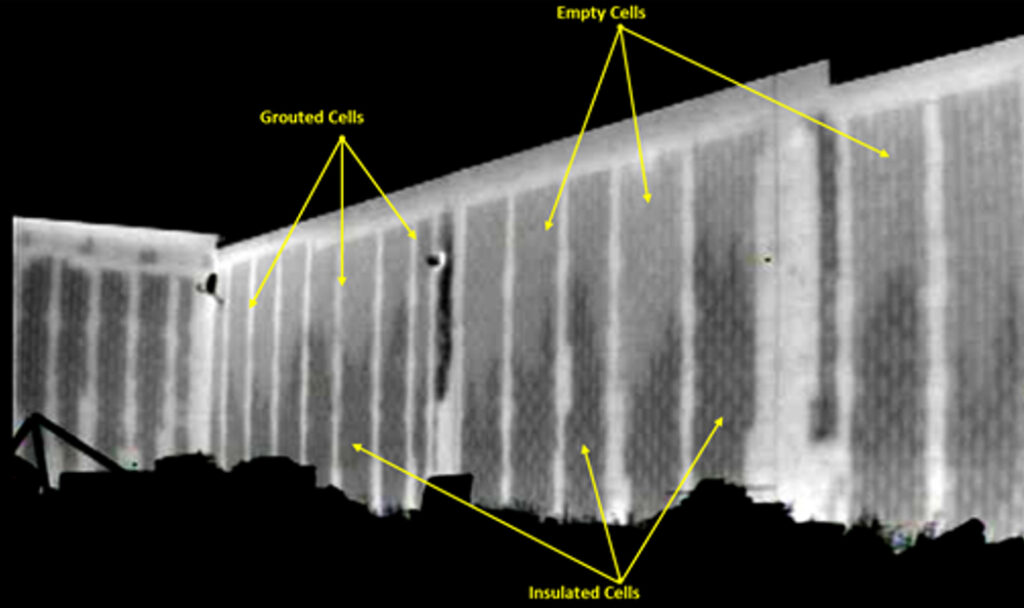

CMU wall survey showing quality of construction

Some of the potential implications of building construction defects include:

- Financial costs: Repairing construction defects can be expensive and the construction company, property owner, or both may bear the cost. In some cases, these costs can be significant and lead to financial hardship.

- Legal liabilities: Either the property owner or other affected parties have taken legal action due to construction defects. This can result in additional costs and complications for the construction company or individual responsible for the defects.

- Safety concerns: In some cases, these defects can pose a safety hazard to people living or working in the building, such as causing a collapse or fire due to a structural or electrical defect.

- Reputational damage: Construction defects can damage the reputation of the construction company or individual responsible, making it difficult for the company to secure future work or for the individual to find employment in the construction industry.

Stucco Delamination

Stucco delamination is a condition in which the stucco, a type of plaster used as a decorative and protective coating on building exteriors, begins to separate from the underlying surface. Water damage, poor installation, or improper curing of the stucco can cause this defect.

The impact of stucco delamination can be significant, as it can lead to water damage, structural damage, and other problems. Additionally, this defect can be unsightly and can decrease the value of the building. It is important to address stucco delamination as soon as it is identified to prevent further damage.

Infrared Technology for Preventive Maintenance

Infrared technology can be used for preventive maintenance by identifying areas of stucco that are not properly bonded to the underlying surface. This is accomplished by using infrared cameras to detect temperature differences on the stucco surface. These temperature differences can help identify areas at risk of delamination.

Early intervention and repairs can prevent further damage and save money in the long run. Infrared technology can also be used to monitor the temperature of the stucco during the curing process. This helps ensure that it is properly cured and less likely to delaminate.

CMU Wall Testing

CMU (concrete masonry unit) wall testing is important for several reasons. It helps to ensure that CMU walls are strong and able to withstand the loads and forces they will be subjected to.

Testing can identify potential weaknesses in walls, such as cracks or inadequate reinforcement. Addressing these weaknesses before they become more serious is important. Data from these tests can be used to improve the design and construction of future walls.

Infrared Technology for CMU Wall Testing

Infrared testing can be performed at any time during construction, and it can detect temperature differences on the surface of CMU walls. These temperature differences may indicate moisture or other potential problems. As a result, infrared testing helps identify areas at risk of failure or issues, and allows for early intervention and repairs.

Furthermore, infrared technology can also monitor the temperature of CMU walls during the curing process. This helps ensure that they are properly cured and less likely to develop problems in the future. The technology is a valuable tool for CMU wall testing and provides valuable data and information that helps ensure the safety and integrity of buildings.

A division of Stockton Infrared Thermographic Services, Inc.